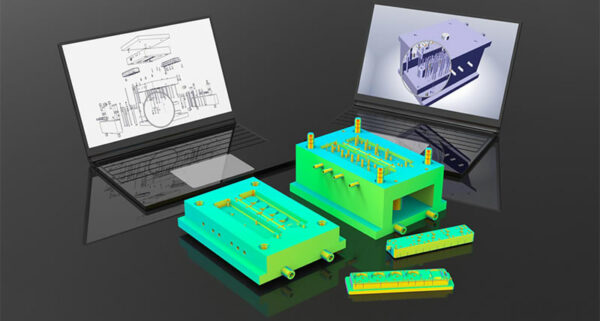

FROM CONCEPTION TO IMPLEMENTATION

Our expertise and support at every stage

Do you need a made-to-measure plastic and/or composite part? A set of technical plastic parts? REFFAY SAS takes your specifications into account, then studies, designs, develops and industrialises your final product to meet your expectations and specifications.

A carefully thought-out, tried-and-tested process

From the first sketch right through to manufacturing, you benefit from a plastics processing partner renowned for its operational and technical skills, as well as its ability to find the most appropriate solutions.

- Our highly resourceful plastics engineer can be involved at any stage of your project.

- We study all the possibilities, with the aim of optimising technologies and costs.

- All injection and compression tests are carried out in-house.

- We are constantly looking for ways to optimise your production.

From design to industrialisation, including the prototype and tooling phases, REFFAY SAS offers you a carefully considered, ISO 9001-certified approach: a turnkey solution for your plastic transformation projects.

REFFAY SAS brings you its expertise in plastics processing at any stage of your project.

Project study

An initial discussion about your project to create a plastic part, in order to examine all

the possibilities and ensure you benefit from our expertise upstream.

This initial meeting will enable us to suggest a suitable process.

This initial meeting will enable us to suggest a suitable process.

Design & development

Development of the part by our team: creation of the part to your predefined specifications, integrating manufacturing and cost constraints, along with technical assistance. First prototyping and tooling phase.

Choice of materials

REFFAY SAS selects the materials best suited to your product and current regulatory standards. Specialising in injection and compression, we transform technical materials: PA, PA6, PA, PBT, TPU, ABS, PC, PP, BMC, CIC, SMC, polyester, vinylester, phenolic powders

Industrialisation

Working in partnership with industrial toolmakers, REFFAY SAS is able to manufacture any type of plastic part, from the most generic to the most complex, requiring specific dedicated tooling. Our high-performance machinery (23 automated presses ranging from 50 tonnes to 800 tonnes) ensures that production takes place in the best possible conditions.

Completion and finishing

Because plastic parts are often integrated into a more complex whole, REFFAY SAS delivers a finished product that fits perfectly into your production flow. That's why our services also include: assembly, painting, marking (pad printing, screen printing, etc.) and made-to-measure packaging.

Quality

In addition to ISO 9001 certification and its application to our processes, REFFAY SAS is committed to a continuous improvement approach (Lean Manufacturing). This quality approach also extends to our suppliers and partners. Our aim is to satisfy our customers through controlled manufacturing quality.

Project management

As an agile, responsive company, REFFAY SAS works in project mode, on all design/manufacturing projects. Our team monitors the project from tool design to final product validation. And our plastics engineer is available as your single point of contact to ensure more flexibility.

Technology monitoring

REFFAY SAS regularly monitors new technologies, materials and market trends. We offer you plastic solutions incorporating the latest innovations, to best meet your needs and expectations.